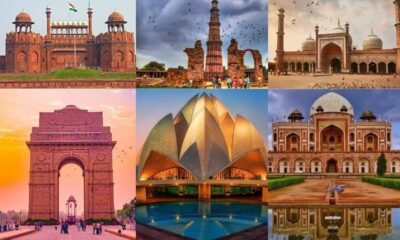

Your bestie is Delhi-bound for the first time, and you’re buzzing with excitement! But wait, a tidal wave of tourist attractions threatens to drown your planning...

Event planning requires very minute information so that everything goes right. Among the minute details, something is always missed while planning an event: Power supply. Events...

Heart diseases require careful management, and exercise is an important component in the management of heart diseases. However, patients with heart ailments should not engage in...

In the pursuit of finding the perfect abode, one often embarks on a journey filled with choices, considerations, and aspirations. Amidst this quest, Royal Residencies emerges...

Sandakozhi celebrated 18 years of release earlier this week. This film holds a special place in director N Lingusamy’s career as it helped him bounce back...

Hema Sharma, who worked on Salman Khan’s home production ‘Dabangg 3’ in 2019, alleges she was mistreated by his security details when she attempted to meet...

No. 1 Dilwala, directed by Thirumala Kishore and featuring Ram Pothineni, Lavanya Tripathi and Anupama Parameswaran as prominent characters is an adaptation of Vunnadhi Okate Zindagi...

Arjun (Manchu Vishnu) and Anu (Kajal Aggarwal), siblings who experienced poverty and exploitation as children, become adults not above engaging in unscrupulous practices to make quick...

This Christmas marks a tale of two Bollywoods. Over on Netflix, Anurag Kashyap and Vikramaditya Motwane — representing Indian cinema’s modernising side — have created the...

Avneet Kaur recently disclosed in an Instagram post that she had auditioned and attended workshops for two films by Aamir Khan – Dangal and Secret Superstar...