A centrifugal pump is a type of hydraulic pump which is built to convert an impeller’s mechanical energy into kinetic energy of an incompressible fluid. Therefore, the centrifugal pump converts the energy with which it is driven. The machinery used to transfer liquids through the hydraulic energy it generates is the centrifugal pump. They are generally used to cause a stream of water to flow, as well as for the operation of liquids. Some of the sectors that use it the most are the chemical industry, the cosmetic industry for the development of creams, or the food industry for the production of all kinds of products.

How does a Centrifugal pump work?

Table of Contents

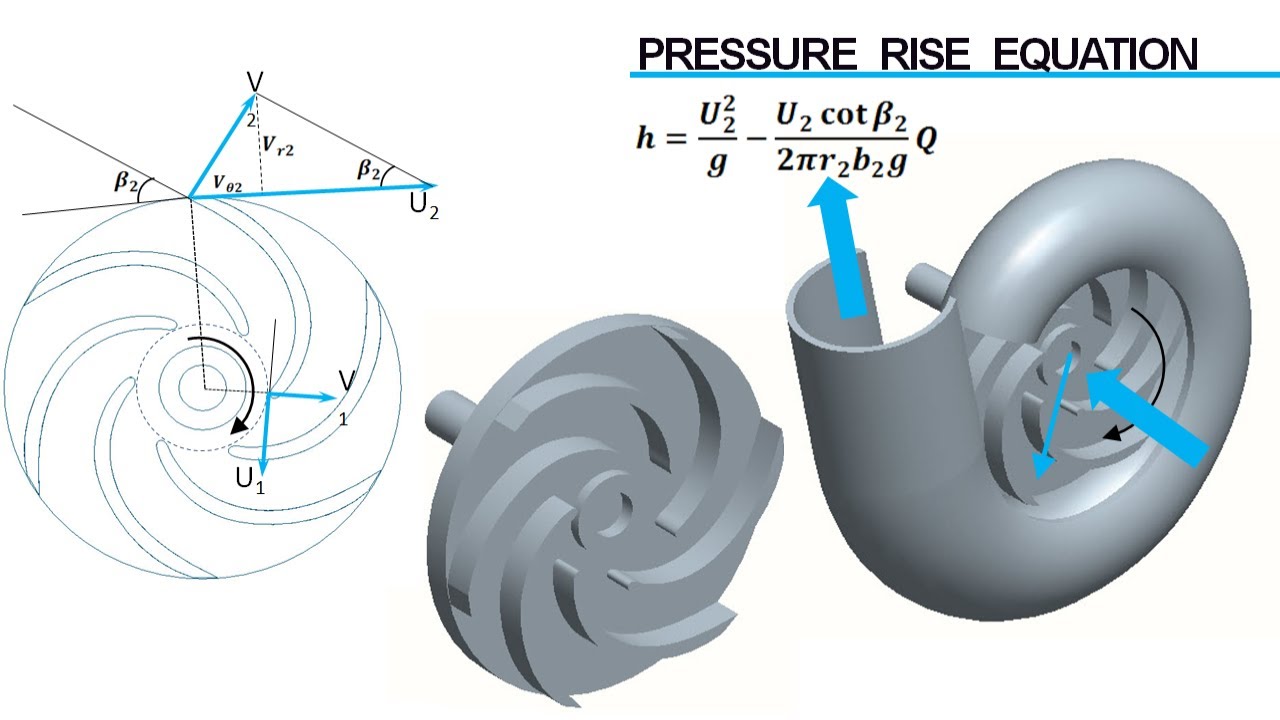

Centrifugal pump operation

To operate a centrifugal pump there are the following steps: first, the fluid enters the center of the impeller of the machine. It has a curved vane, which serves to guide the fluid. Afterwards, due to the centrifugal force produced by the pump, the fluid is driven to the outside, where it is collected by the casing or body of the pump. Finally, thanks to the structure of the machinery, the fluid is led to the outlet pipes. There are different models of pumps that allow us to solve the problems that arise in the transportation of the product. Types of centrifugal pumps are:

- Helical turbine centrifugal pumps,

- Liquid ring pumps,

- Progressive cavity pumps,

- Gear pumps,

- Flexible impeller pumps,

- Lobular pumps,

- Peristaltic pumps.

How a centrifugal pump works?

If you think about all the industries that need to move industrial fluids, you would be thinking that millions of liters of fluids are moved per day. And not only industries need the movement of fluid, but also homes, hospitals, businesses, and many more institutions. It gives us a guideline of the importance of the elements that collaborate in the movement of the fluid to make them reach the required points. Among these elements one of the most important is the centrifugal pump.

The operation of centrifugal pumps is based on a rotor. It is the element that transfers the energy received by an electric motor to the fluid. It is achieved since the rotor has blades that are responsible for pushing the fluid, generating an increase in its speed and therefore in its kinetic energy. In turn, when the fluid is rotating in the blades, it receives a centrifugal force that increases its pressure and with this its internal energy evens more.

Differences between centrifugal pump and peripheral pump

The centrifugal pump and peripheral pump have the same function but different applications due to differences in their characteristics. Centrifugal pumps are capable of working with a higher flow than peripheral ones because they can exert greater pressure. The turbines centrifugal pump is larger than the peripheral pump turbines. If you think in economic terms, peripheral pumps are costlier than centrifugal pumps.

Widely used due to its application

The centrifugal pumps operate on the principle established in the Euler equation. They are generating machines that facilitate the circulation of fluids so that they can overcome the greater pressure they face. Fluids do not need any additional energy when they go from a place where there is more pressure to one where there is less pressure. The impeller is installed inside a casing so that the water that moves outwards will be collected inside it and it will move in the same direction of rotation of the impeller to discharge the nozzle.

Take as an example the air that is enclosed in a balloon. If you release the knot, it will deflate without a problem because the air inside the balloon is subjected to more pressure than the air outside it. The liquid, before entering the pump, cannot circulate through the pipes because the air pressure in the pipe is higher than that in the tank where the water is. It is why they need that additional energy provided by the pump to increase their pressure capacity.

Conclusion:

A centrifugal pump is a type of pump which helps in transforming an impeller’s mechanical energy into fluid pressure energy. The centrifugal pump converts the mechanical energy with which it is driven into hydraulic energy. The centrifugal pump is the most widely used equipment today to drive water or other fluids such as fuels. We will find it in irrigation systems, drinking water distribution, and in factories or industries of all kinds.