Industrial Dewatering: A Cornerstone of Sustainable Development

Table of Contents

Today’s industrial landscape is increasingly characterized by a pressing need for sustainable practices that align with stringent environmental goals. This growing awareness has highlighted the role of industrial dewatering as an essential cog in the wheel. Industrial dewatering, which involves the separation of liquids from solids, is a critical process in many sectors, including mining, construction, chemical manufacturing, and wastewater treatment. It is an area where the application of mechanical dewatering techniques has emerged as both an environmental necessity and an economic opportunity. Efficient dewatering helps manage waste products sustainably and supports industries in curtailing their operations’ adverse effects on the natural world. By highlighting and integrating dewatering into industrial processes, businesses optimize water usage and create an avenue for water reclamation and reuse, thus pushing the envelope on comprehensive resource sustainability.

Examining the Environmental Benefits of Dewatering

Dewatering processes carry a suite of environmental benefits that extend well beyond the immediate facilitation of water removal. Central to these benefits is the substantial decrease in water utilization. This conscious reduction plays an essential role in the broader scheme of conservation efforts by mitigating the scarcity of water resources. Furthermore, dewatering contributes to a consolidated approach to managing ecological footprints by lessening the strain on municipal and industrial water treatment operations. It enables industries to handle wastewater and solid waste effectively, which is imperative for maintaining ecosystem integrity. Additionally, a more concentrated waste stream translates into lower costs for transportation and disposal, further motivating the shift toward sustainability from both environmental and economic viewpoints.

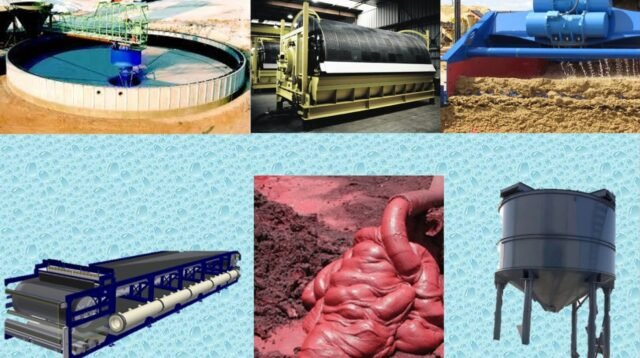

Technological Innovation in Dewatering Systems

Innovation within industrial dewatering systems is a beacon of progress, indicating a commitment to ecological integrity and operational efficiency. The latest advancements in the field are enhancing mechanical dewatering tools, making them more sophisticated and less energy-intensive. Modern equipment, such as centrifuges and belt filter presses, exhibits an industry-wide push for higher productivity and a decreased environmental footprint. As a result, industries are witnessing a revolution where mechanical separation processes can achieve greater precision, energy conservation, and, ultimately, a more significant return on investment. Exploration of the recent research can provide industry professionals and stakeholders with deeper insights into the monumental beneficial impacts of these technological innovations.

The Role of Policy and Regulation in Dewatering Practices

Stringent government policies and environmental protection regulations often define the legislative landscape surrounding dewatering practices. These legal frameworks aim to ensure that industrial dewatering adheres to high standards of environmental care. They outline the necessary measures and benchmarks that industries must meet to maintain compliance. The enforcement of regulations — such as those enacted by the Environmental Protection Agency on industrial wastewater — plays a critical role in directing industries toward more environmentally responsible dewatering practices. By upholding these norms, industries are not only following a legally mandated path but are also acknowledging their role and responsibility towards fostering a greener future. Compliance with these regulations can also lead to improved corporate image, consumer confidence, and possibly even tax incentives or rebates, which underscore the multifaceted value of sustainable practices.

Challenges and Solutions for Sustainable Dewatering

Adopting sustainable dewatering techniques has many benefits, but there are drawbacks as well. Industries often face challenges such as hefty initial investments for high-quality equipment, ensuring operational efficiency, and meeting strict regulatory standards while maintaining profitability. These challenges call for a multifaceted approach that includes continuous innovation, government incentives, and education for all stakeholders involved. Industries can uncover practical and sustainable solutions by bridging the gap between fiscal feasibility and environmental ethics. Companies must get creative, seeking breakthroughs in dewatering technology and leveraging collaborative opportunities that may arise from public-private partnerships to overcome these hurdles and capitalize on the long-term benefits of a sustainable dewatering approach.

Future Outlook: The Next Wave of Dewatering Innovations

The trajectory of dewatering innovation points toward a future where technology and sustainability go hand in hand. Industry analysts predict an ongoing emphasis on energy-efficient systems, greater automation in dewatering processes, and integration of these solutions into broader sustainable business models such as the circular economy. The anticipation surrounding technological leaps, coupled with probable shifts in policy, suggests that the next wave of innovations will likely hold unprecedented efficiency gains and even more significant environmental benefits. As the industrial world prepares for these advancements, the commitment to ecological sustainability remains critical, charting the course for responsible growth and protecting our planet’s precious water resources.